Caffenol Is a Great Developer!

For the past couple of years, I’ve been using Caffenol (film developer made with instant coffee) almost exclusively, for my black and white film developing. I have chosen some basic Caffenol recipes from Caffenol.org and through a lot of testing, I have adjusted those recipes to suit my own personal film developing preferences. By understanding how each of the ingredients contributes to the overall film developing effect, I have managed to refine the process and achieve excellent results.

Mixing a batch of Caffenol developer isn’t simply about combining the ingredients; success is dependent on how those ingredients are mixed, as well as developing time, temperatures, and agitation.

Caffenol ingredients. Washing soda, instant coffee and ascorbic acid.

The key to mixing a reliable batch of Caffenol is the same as any scientific exercise; I try to control as many variables as possible. Purity of ingredients, precise timing and temperature. By following these principles, results will be consistent and repeatable.

As a photographer who loves to shoot dance, events and documentary photography, I like to use film in the ISO 400 range, such as Kodak Tri-X 400. It’s a good, versatile film that can easily be pushed a few stops when necessary, like with low light, or mixed lighting situations. When properly exposed and developed, Kodak Tri-X 400 exhibits very good dynamic range, and is useful for a wide range of photographic styles.

Different developers have different effects, depending on their chemistry. The most popular developers, like Kodak HC-110, give Kodak Tri-X 400 decent sharpness and contrast, with good mid tones, depending on the light. Adox Rodinal, also a very popular developer, provides good contrast, but pronounced film grain, and somewhat poor acuity/sharpness. Over the years, Kodak’s HC-110 was my go-to developer, and Adox Rodinal was what we used back in the classroom in my school days.

A couple of years ago, I decided to try Caffenol developer for the first time. To be honest, I wasn’t expecting very much, as many of the examples I’d seen online weren’t exactly stellar, I was seeing under developed, washy, dull or flat looking images. It seemed to me (and probably to many other people) that Caffenol was something you could use to develop film if you were out of other options, and that the mainstream developers were much better. I soon learned that this was not true at all. Caffenol is not only an excellent developer, I believe it is (in my opinion) better than any other black and white developer, as long as it is mixed and used properly.

One of the variables—an important one—is your choice of instant coffee. There are many brands of instant coffee available. You need a brand that has a decent amount of caffeic acid. Caffeic acid is the active ingredient in Caffenol developer. Caffeic acid is a plant-based phenol. Phenols are the active ingredient in most film developers, however, commercial developers use synthetic phenols such as hydroquinone, mainly because they have good storage life, and remain active much longer than the natural, plant-based ones. Most commercial developers contain ingredients that are toxic to the environment, whereas Caffenol ingredients are completely environmentally friendly, and can be dumped down the drain. This is yet another good reason to use Caffenol as your film developer.

So, as I mentioned earlier, your choice of instant coffee is important. I’ve tried several brands, and the most effective kind I’ve tried is Taster’s Choice instant coffee. Just the basic, original Taster’s Choice brand. You may find other brands out there that are effective as well. Just avoid the decaffeinated brands, as they will not work. An interesting observation; the most bitter tasting instant coffee seems to work best. I can only speculate the reason for this—perhaps because the bitter coffee has more caffeic acid in it.

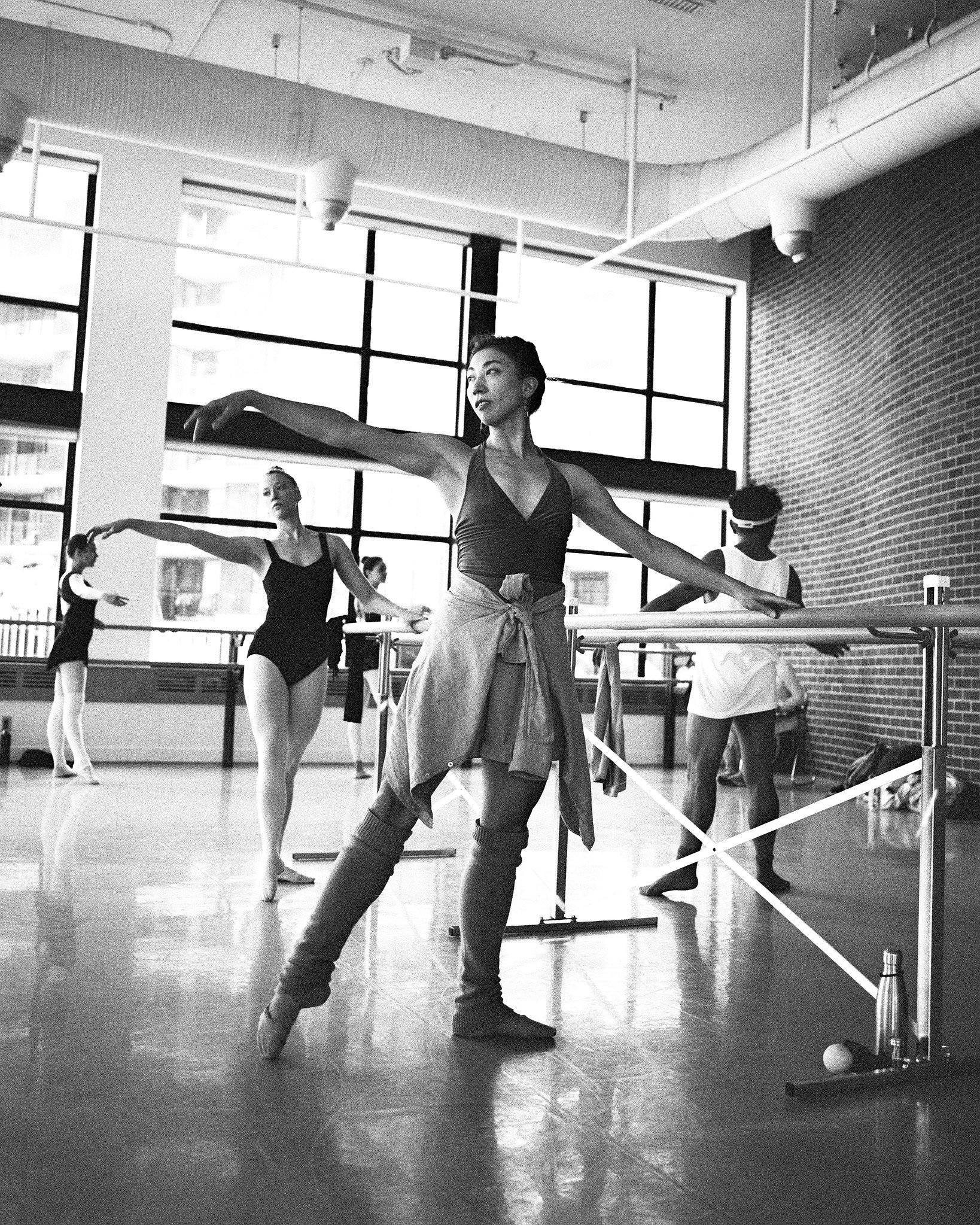

Recently I was asked to shoot a ballet class in a large university dance studio. I decided to shoot the dancers on Kodak Tri-X 400 black and white film, which I would subsequently process with Caffenol. The studio was large, with high ceilings and nice big windows, but the light was quite low, and so I knew I needed to push my film to ISO 1600 in order to bring up my shutter speeds to capture the action.

Interestingly, through searching the internet, I could not find examples of, or recipes for Caffenol specifically for push processing film. In fact, all I could find was discussions within photography forums on the topic of pushing film with Caffenol, wherein the general consensus was that you cannot use Caffenol to push process film, due to the limited time in which Caffenol remains active. However, I was not convinced. I knew there had to be some way to make Caffenol more effective for push processing. With some testing and calculations, I was able to produce a recipe and method that works, and is indeed very effective.

The biggest problem people were facing when experimenting in push processing with Caffenol was the short lifespan of the developer. Oxidization begins immediately once the ingredients are mixed. A fresh batch of Caffenol remains viable for roughly 20-30 minutes, and even less when it reacts with the film. For conventional developers, push processing film 2 stops generally requires approximately 2.5x developing time. It works well, because the active ingredients in the developer remain adequately potent for the extra developing time required for push processing. This is one of the advantages of synthetic phenols over natural, plant based phenols.

So this was my dilemma; How do I extend or sustain the lifespan of my Caffenol developer? Well, I figured it out. I increased the volume of ascorbic acid, and also the volume of the sodium carbonate. The added ascorbic acid would prevent the film from fogging—a less desirable effect of film sitting in Caffenol developer over a long period of time—and additional sodium carbonate would slightly extend the potency of the developer. The other major important change was the frequency of agitations. I needed to agitate the film less frequently.

The normal agitation routine for developing film is to agitate continuously for the first minute, and then about 10 seconds every minute, for the duration of the developing time. I don’t want to go into too much detail here on what exactly is happening chemically during the process of agitation because it would be a very long article, and so I will write a brief explanation; The reason we agitate film is to refresh the chemistry that is reacting with the emulsion layer of the film. When the developer ingredients react with the film, a reaction layer/barrier is formed on the surface of the film. Agitation washes off that reaction layer and enables the process to continue with a fresh layer of developer. More agitation will cause a stronger, more rapid reaction. It is for this reason that I theorized that less agitation would sustain the potency of the Caffenol developer for a longer period. I change the agitation routine from 10 seconds every minute, to 10 seconds every 4 minutes. It worked! The Caffenol developer lasted just long enough to successfully develop film that was pushed two stops! The total developing time was 28 minutes.

Here is the Caffenol recipe, and the method I used with my Kodak Tri-X 400 ISO film, pushed to 1600. This is to make 1 litre of developer:

Ingredients:

40g Tasters Choice instant coffee

40g sodium carbonate

20g ascorbic acid

Equipment:

Digital scale

Digital thermometer

Beakers

Kettle

Use an accurate digital scale to measure the volume of each of the ingredients. Your scale must be sensitive enough to measure volumes in grams. Measure your ingredients into separate beakers, or containers. Important: Do not mix the dry ingredients together!

Empty the instant coffee into 1000ml (or larger) beaker. Add a small amount of boiling water. ( I use about 100ml or so). Stir the coffee until fully dissolved. You can stir the solution with a stirring rod, a spoon, or you can swirl it in the beaker. Just be aware it is boiling hot.

Add some cold water (I add enough cold water to bring the solution up to about half) and then add the sodium carbonate (wash soda). Stir until all of the sodium carbonate is dissolved (approximately 3 minutes). Add the remaining cold water to bring the total volume up to 1000ml, before adding the ascorbic acid.

Check the temperature of the solution. At this point, it should be at the developing temperature of 20 °C. If the solution is hotter than 20 °C, you can add an ice cube until it cools to 20 °C. Be careful not to add too much ice. You don’t want to exceed the solution volume of 1000ml.

Add the ascorbic acid, and stir until fully dissolved. There will be a slight thermogenic reaction when adding the ascorbic acid, and there may be a bit of foaming. This is normal. The fully mixed Caffenol solution is now ready for developing. [Note: The oxidization process of the caffenol begins as soon as you’ve finished mixing your ingredients. You must have your developing tank prepared for developing, as the Caffenol will only be viable for approximately 25-30 minutes after mixing.]

Developing:

[Note: This developing formula/method is intended specifically for developing 400 ISO film that has been pushed to 1600. I have tested this formula with Kodak Tri-X 400 and Ilford HP5 Plus 400 (both pushed to 1600). I have not tested this formula on other films yet. I will be testing other films and recording the results in the near future.]

Set your developing timer for 28 minutes.

Check your Caffenol temperature. It should be 20 °C.

Pour your Caffenol developer into your developing canister. (I use a Paterson multi-reel developing tank which will hold 3 rolls of 35mm film, or 2 rolls of 120/220 film. For this canister, I use the entire 1000ml volume of Caffenol solution. If you have a smaller canister, you can use 500ml of the Caffenol solution, or enough to fill the canister but still allow for agitation.)

Start your developing timer.

Continuous agitation for the first minute, then agitate for 10 seconds every 4 minutes for the rest of the development time.

When the developing is complete, pour out the Caffenol and add your stop bath solution. Alternatively, if you’d rather not use stop bath, you could rinse your film with water instead, which will also stop the development process.

Agitate stop bath solution constantly for 1 minute.

Pour your stop bath solution back into a container (it can be reused several times).

Pour your fixer solution into the developing canister. Continuous agitation for the first minute, then agitate for 10 seconds every minute, for a total of 5 minutes. I use Ilford Rapid Fixer for my fixing solution. When fixing is finished, pour it into a container (it can be reused several times).

Rinse your film for several minutes (I rinse for about 3 minutes) with running water.

Use a wetting agent to prevent water spots on your film. I use Ilford Ilfotol wetting agent for 1 minute after rinsing the film. Hang your film to dry for at least 8 hours before handling.

Notes:

-Caffenol is intended as one-shot developer, and should not be reused. When finished developing, it is safe to discard the Caffenol down the sink.

-Normal caffenol developing time is 11:00 for Kodak Tri-X 400 (pushed 2 stops) x 2.5 = 27.5 minutes. I rounded the development time to 28 minutes.

-I added an additional 5g of sodium carbonate. (The standard is 35g.) I decreased agitation from 10 seconds every minute to 10 seconds every 4 minutes.

Be sure to check out Caffenol.org. It is a vast wealth of info on everything Caffenol related.

UPDATE:

Here is the Caffenol developer recipe for standard developing, for ISO 400 black and white film such as Kodak Tri-X 400, or Ilford HP5 400:

40g Taster's Choice instant Coffee

35g Sodium Carbonate

20g Ascorbic acid

Directions:

To make 1 litre of solution:

Empty instant coffee into 1000ml beaker. Add a small amount of boiling water. Stir the coffee until fully dissolved.

Add some cold water and then add the sodium carbonate (wash soda). Stir until all of the sodium carbonate is dissolved (approximately 3 minutes). Add the remaining cold water to bring the volume up to 1000ml, before adding the ascorbic acid.

Check the temperature of the solution. At this point, it should be at developing temperature, (20 °C). If the solution is hotter than 20 °C, you can add an ice cube until it cools to the desired temperature. Be careful not to add too much ice.

Add the ascorbic acid, and stir until fully dissolved. There may be a slight reaction when adding the ascorbic acid. This is normal.

When the Caffenol is fully mixed, it is ready for developing. Use the Caffenol within 15 minutes, as it oxidizes quickly.

Developing time is 11 minutes at 20 °C

For best results, Caffenol is intended as one-shot developer, and should not be reused.